Sustainability is becoming increasingly important, the recycling of everyday items, including plastic slippers, is gaining more attention. Plastic slippers, commonly known as flip-flops, are one of the most popular types of footwear globally. Unfortunately, they are also a significant source of plastic waste. Many are discarded after a short lifespan, ending up in landfills or polluting oceans and waterways. However, with advancements in recycling technology, plastic slipper recycling is not only possible but also crucial for reducing plastic waste and promoting environmental responsibility.

Plastic slippers are made from materials like polyurethane, EVA (ethylene-vinyl acetate), and PVC (polyvinyl chloride), all of which are non-biodegradable. Once discarded, they can persist in the environment for hundreds of years, contributing to the growing plastic pollution crisis. Recycling these materials can help divert waste from landfills and reduce the harmful environmental impact associated with plastic waste. Additionally, the recycled materials can be repurposed into new products, reducing the demand for virgin plastic production, which in turn lowers carbon emissions and conserves natural resources.

The Plastic Slipper Recycling Process

The process of recycling plastic slippers involves several steps:

- Collection: The first step in plastic slipper recycling is collecting the discarded slippers. This can be done through dedicated recycling programs or partnerships with organizations focused on reducing plastic waste.

- Sorting and Cleaning: Once collected, the slippers are sorted based on the type of plastic they are made from. They are then thoroughly cleaned to remove any dirt, debris, or contaminants.

- Shredding: The cleaned plastic slippers are shredded into small pieces, making it easier to process them further.

- Melting and Reprocessing: The shredded plastic is melted down and reprocessed into raw materials, such as plastic pellets. These pellets can then be used to manufacture new plastic products, including shoes, toys, construction materials, or even more slippers.

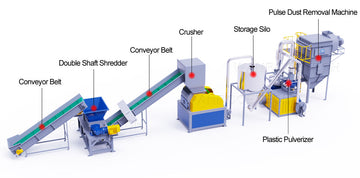

Plastic Slipper Recycling Equipment

To carry out the recycling process efficiently, specialized recycling equipment is necessary. This equipment helps streamline the process, ensuring that the slippers are properly shredded, melted, and repurposed into new materials. Here are some of the essential plastic slipper recycling machines:

1. Plastic Shredders

Plastic shredders are crucial in the recycling process. These machines break down the slippers into small, manageable pieces. They are designed to handle various types of plastics, including the EVA and PVC commonly found in slippers. By reducing the size of the slippers, shredders make the melting and reprocessing stages more efficient.

2. Plastic Granulators

After shredding, the plastic pieces are further processed using granulators. These machines grind the shredded material into even smaller granules or pellets, which can then be melted and reused. Granulators help to ensure that the recycled plastic is of a uniform size, making it easier to repurpose into new products.

3. Plastic Densifiers

Plastic densifiers are used to compress plastic materials into dense, manageable forms. For lightweight and bulky plastic items like slippers, densifiers help reduce the space they take up during transportation and storage. This equipment is particularly useful for businesses that collect large amounts of plastic waste and need to transport it efficiently to recycling facilities.

4. Extruders

Plastic extruders are essential in the final step of the recycling process. These machines melt down the plastic granules and form them into new materials, such as plastic pellets, sheets, or other shapes that can be used in manufacturing. Extruders allow for a wide variety of recycled plastic products to be made from the recovered material.

For companies involved in footwear manufacturing or retail, investing in plastic slipper recycling equipment can be a game-changer. Not only does it help reduce waste, but it also enables businesses to contribute to the circular economy by repurposing materials that would otherwise end up in landfills. Additionally, as consumer demand for eco-friendly and sustainable products grows, companies that prioritize recycling are likely to see increased customer loyalty and brand reputation.

Recycling plastic slippers is a small yet impactful way to contribute to environmental sustainability. With the right plastic slipper recycling equipment, businesses and organizations can take significant strides in reducing plastic waste and supporting a circular economy. By reprocessing plastic waste into new materials, we can keep harmful plastics out of the environment while conserving valuable resources.